Industries Served

Agriculture

Food Processing Equipment

Glass & Ceramics

Heavy Industry

Logistics & Distribution

Manufacturing

Material Handling

Packaging & Converting

Warehouse & Distribution

Flat Glass Processing

Custom Conveyor has been working with the flat glass industry for decades, and we understand its unique challenges. We are experienced in gentle, non-marking handling of wood and vinyl window and door components as well as handling complete units in packaging and warehouse operations.

Our specialty, however, is in handling waste glass from cutting, tempering, and other flat glass processes. Our unique glass breaking and conveying equipment can improve cutting table throughput, reduce operator fatigue, and minimize injury risk in your facility. These systems are tailored to work directly with your existing processing equipment. The breakers receive scrap glass from manual breakout tables or automated axis breakers and convert it into cullet which is easily transportable by our bulk conveying systems.

From a simple above-grade system for a single low-volume breakout table to a multi-line, plant-wide system that brings all of your waste glass to one centralized location, Custom Conveyor can design a cullet system to meet your specific needs.

For more information, check out our Cullet Systems.

Food Production

When it comes to food manufacturing, every step in the process must be efficient, clean, and precise. There is little margin for error, whether it comes from people or the machines that help them.

Custom Conveyor supports our food industry partners with simple, reliable conveyor designs that incorporate best practices for sanitary design and minimize loss.

We serve customers in the bakery, meat processing, produce, and sanitary packaging segments with custom solutions to help move their products and their business forward.

Unit Handling

Whether your product weighs six grams or six tons per unit, we can design equipment to move it where you want, when you want.

Custom Conveyor specializes in tackling unique layouts, difficult transitions, and changeovers for handling multiple products on one line. All of these, and more, are examples of challenges we look forward to helping you solve.

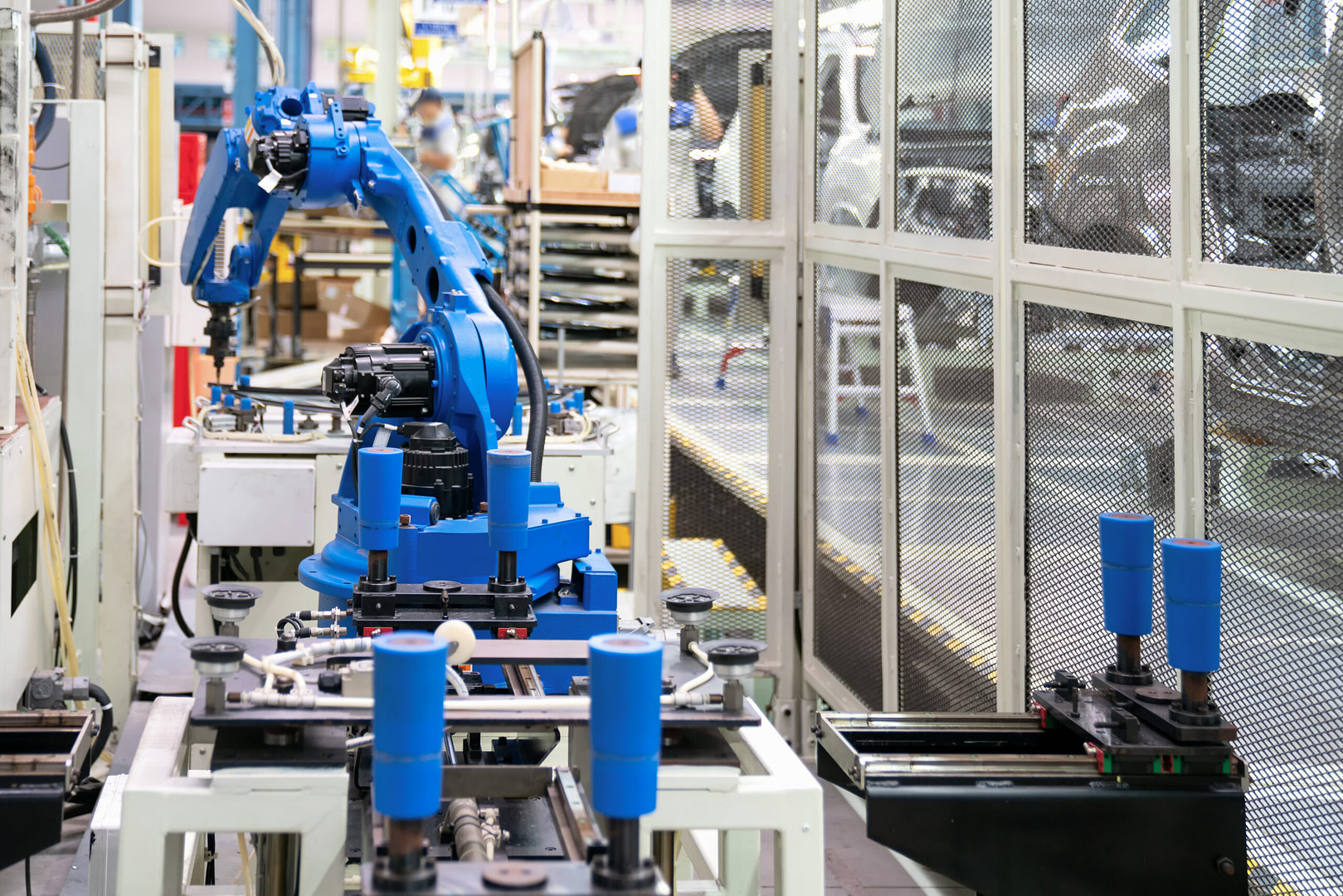

We know that automation cells often depend on consistent, reliable positioning of products both going in and coming out. Our engineers will craft effective technologies, create custom designs, and implement proven methods to get your parts flowing through your automated process with lights-out dependability.

Bulk Handling

Whether it’s gravel, wood chips, sand, glass cullet, steel chips, seed, or any other material that you are needing to move in a bulk stream, Custom Conveyor can help.

We can design a system using flighted belts, drag flight chains, troughed belts, cleated sidewall belts and many other technologies which can move your bulk materials rapidly and accurately. We start by understanding what it is you need to move and how you need to move it, then apply our experience to get the throughput you need with minimum spillage.

We can design long runs of conveyor to cover significant distances at your facility, high lifting solutions to elevate your bulk stream, as well as precise conveyors to meter material at a desired rate. We can also help you to develop weight in motion scales to measure the product flow. Call us today to get started on solving your bulk material challenges.

Agriculture

Custom Conveyor is centrally located in America’s heartland, which puts us in a prime position to partner with the agriculture sector in advancing the state of the art for agricultural production.

Ag companies leverage our experience and engineering resources to help develop light weight, compact conveyance systems for their mobile platforms. Whether it’s a production run or a prototype in support of a new concept, we are here to help.

We have also partnered with producers and entrepreneurs to help them develop machines for processing and separating materials. We are more than just conveyors, and if you can imagine the machine, we can help you make it a reality.

Warehouse

Custom Conveyor will help you get the right equipment for moving cases or pallets through your shipping department, distribution center, or warehouse.

We will work with you to understand the flow you would like to achieve and to generate the layout that will get you the best results. We can specify and design custom live roller conveyors, chain conveyors, belt conveyors, turntables, and vertical lifts to get your products from A to B.

Packaging

If you are looking to develop an automated packaging line for your facility, let us help! Our in-house design team can generate a custom solution to support the packaging line that you need to get your output flowing.

Automated packaging can be the key to improving the throughput of your production system. At Custom Conveyor we understand that products come in a huge variety of sizes, shapes and weights, and custom solutions often provide the best throughput and the highest overall equipment effectiveness. Whether small or large, high speed or highly variable products, we will work with you to get the right solution for the right price.

Contract Fabrication

We build our products using a team of skilled engineers, designers, fabricators and assemblers in concert with a strong network of suppliers… and we can build your products with them too!

We are happy to help others provide American made products to their markets. Custom, one-off, short run, or long term production schemes are all available. If you have a need to supplement or outsource your production, get in touch!

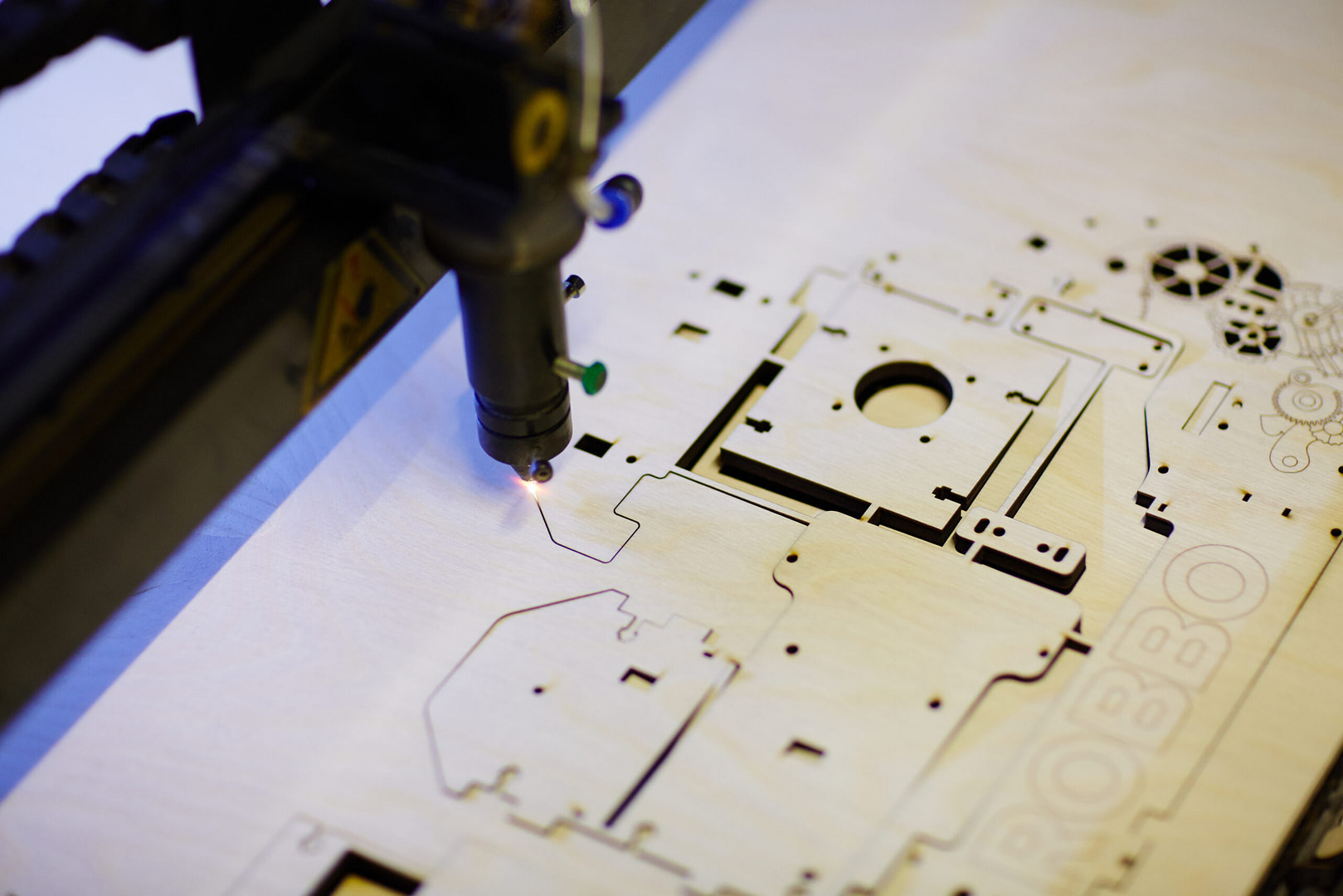

Laser Cutting

- 3kW Fiber laser

- 6' x 12 Sheet size capability

Bending

- 12' 300 ton break press

- +/- 1 degree general bending tolerance

Welding/Fabrication

- Carbon Steel MIG/Pulse MIG/TIG

- Stainless Steel Pulse MIG/TIG

- Aluminum TIG

Assembly

- Mechanical assembly

- Wiring and electrical testing

Engineering Support

- Model or draw parts from your concepts

- Convert and prep files for laser cutting

Custom Conveyor Solutions

Our Step-By-Step Process

At Custom Conveyor, we work with your team from conceptualization to completed product to ensure that the solution we ship is the one that you need. We will examine your application, work with you to determine the best solution, then manufacture it to your specifications. The process is thorough and results in a quality piece of equipment.

If you are starting from a problem, and do not yet know how to solve it, we are here to help.

We will work with your engineering, maintenance, or operations staff to assess the needs of your process and develop an efficient solution that considers upstream and downstream process steps, as well as future growth plans.

Afterwards, we will then translate this into a comprehensive list of requirements, setting a clear path forward.

Whether you worked with us to help determine the need, or you already know what you are looking for, we will apply our engineering talent to outline a machine design that meets or exceeds your requirements. Our team will work with your decisionmakers to balance capability and cost for a truly custom-engineered solution.

Once we have a machine design locked in, we fabricate and assemble the solution in the same facility where it was designed. This tight integration gives us control over quality, and flexibility in our timelines.

During this assembly process, our engineers and fabricators work together to perform validation runs and real-world optimization tests while the design is still easily modified. All this ensures the product is ready to run when it hits your floor.

Contact Custom Conveyor today to find the solution you are looking for.