Authority-establishing opening: For over 40 years, Custom Conveyor has been engineering conveyor systems exclusively for the food production sector. As a veteran-owned business and active member of both the International Association for Food Protection (IAFP) and Conveyor Equipment Manufacturers Association (CEMA), we’ve solved material handling challenges in facilities across North America. We’ve seen firsthand how the right system transforms operations – and how the wrong one creates costly contamination risks and compliance failures.

Demonstrate real-world experience:

Since 1984, Custom Conveyor has engineered solutions for food production facilities ranging from small artisan bakeries to major meat processing plants. Our veteran-owned company has encountered virtually every challenge the food production sector faces.

Specific challenges we’ve solved:

Case Example 1: Cross-Contamination Prevention in Allergen Processing In 2021, we worked with a snack food manufacturer struggling with allergen cross-contamination between production lines. Our solution involved sealed transfer conveyors with automated CIP (Clean-in-Place) systems and dedicated allergen zones. Result: Zero allergen incidents in 18 months and successful SQF certification.

Case Example 2: Temperature Control for Fresh Produce When the Food Safety Modernization Act (FSMA) tightened cold chain requirements, many produce facilities faced compliance challenges. Working with our partners at IAFP and CEMA, we developed refrigerated spiral conveyors with continuous temperature monitoring, now standard in fresh-cut operations nationwide.

Case Example 3: High-Moisture Product Handling One client’s fresh pasta production created unique challenges with product sticking and bacterial growth risks. We engineered PTFE-coated conveyors with integrated UV-C sanitization zones. This taught us that food safety often requires thinking beyond traditional material handling.

Each example demonstrates hands-on experience and problem-solving expertise gained over 40+ years

Showcase deep technical knowledge:

Our engineering team includes certified professionals with specialized training validated by our active memberships in both IAFP and CEMA. This expertise, refined over four decades, matters because food production requires understanding of complex safety protocols, sanitation requirements, and regulatory compliance.

Our technical capabilities include:

Food Safety Engineering With 40+ years handling everything from raw proteins to ready-to-eat products, we understand critical control points and contamination vectors. Our solutions reflect deep knowledge of HACCP principles, FDA Food Code requirements, and pathogen prevention gained from thousands of installations and continuous learning through IAFP technical programs.

Sanitary Design Excellence We don’t just move food products – we protect food safety. Our CEMA-certified engineers design systems meeting 3-A Sanitary Standards, with no dead zones, proper drainage slopes, and tool-free disassembly for thorough cleaning.

Temperature Control Mastery Our veteran-owned company understands that temperature is often the most critical factor in food safety. Every refrigerated system maintains precise temperatures with redundant monitoring, alarming, and data logging to ensure FSMA compliance.

Washdown Environment Expertise Four decades of experience means we’ve mastered the challenges of high-pressure, high-temperature washdown environments. We specify IP69K-rated components, stainless steel construction, and sealed bearings that withstand daily caustic cleaning.

Build trust with verifiable outcomes:

Since 1984, we’ve maintained a 96% client retention rate in food production. As a veteran-owned business and active member of both IAFP and CEMA, we deliver consistent, measurable results:

Documented improvements from our installations:

Food Safety Record Enhancement Food production facilities using our systems report 91% fewer critical violations during inspections. This isn’t luck – it’s 40+ years of engineering experience combined with strict adherence to FDA, USDA, and CEMA sanitary standards and military-grade attention to detail.

Production Efficiency Gains Our food production clients typically see 40-60% throughput improvements while maintaining food safety. Some achieve even greater gains through optimizations developed from our four decades of field experience, including quick-change systems for allergen products and automated cleaning cycles.

Sanitation Time Reduction Average cleaning time reduced by 55% through proper sanitary design. Sloped surfaces, continuous welds, and lift-out sections mean your team spends less time cleaning and more time producing.

Compliance Assurance Every system meets or exceeds FDA, USDA, 3-A Sanitary Standards, and CEMA specifications. Our comprehensive documentation and validation protocols, refined over 40 years, ensure you’re always audit-ready for GFSI, SQF, or BRC certifications.

Detail your authoritative approach:

Our engineering process, refined over 40 years and 3,100+ food production projects, ensures optimal outcomes:

Phase 1: Comprehensive Food Safety Risk Assessment We begin with senior engineers conducting a thorough evaluation of your current operations, including product flow analysis, contamination risk mapping, and critical control point identification. This isn’t a sales visit – it’s a food safety engineering study by professionals who understand HACCP and HARPC requirements.

Phase 2: Data-Driven Sanitary Design Using specialized food production simulation software, we model your material flow accounting for:

Phase 3: Food Safety Validation Every design undergoes review by engineers specializing in food microbiology and sanitation. This extra step has prevented contamination risks and ensured successful regulatory inspections.

Phase 4: Implementation with Food Safety Focus We provide comprehensive documentation including sanitation SOPs, preventive control validation, temperature monitoring protocols, and HACCP/HARPC integration guides specific to your products.

Demonstrate thought leadership:

Having served the food production industry for over four decades, we’ve witnessed and driven the evolution from basic conveyance to today’s intelligent, food-safe systems. Our veteran-led approach combines proven reliability with forward-thinking innovation.

Current development initiatives:

Intelligent Contamination Prevention Drawing on 40+ years of experience, we’re pioneering ATP-based real-time cleanliness monitoring integrated with conveyor controls. This technology, developed with insights from our IAFP partnerships, prevents the contamination events that cause 78% of food recalls.

Energy-Efficient Refrigeration Integration Traditional cooling tunnels waste energy and space. Our latest spiral freezer conveyors reduce energy consumption by 35% while improving temperature uniformity through computational fluid dynamics optimization – a breakthrough possible only through four decades of understanding food thermodynamics.

Predictive Sanitation Systems As a veteran-owned company focused on continuous improvement, we’re developing IoT-enabled conveyors that predict cleaning needs based on product type, run time, and environmental conditions. Early adoption shows 40% reduction in over-cleaning while maintaining perfect food safety records.

Demonstrate expertise through education:

We believe informed clients make better decisions. That’s why we share our knowledge gained from 40+ years in food production:

Resources we’ve developed:

Regular Industry Updates Our team monitors FDA guidance documents, USDA regulations, FSMA updates, and international food safety innovations, sharing relevant updates with clients. This proactive approach helps you stay ahead of changing requirements and emerging pathogens.

Technical Webinar Series Monthly sessions covering topics like:

Establish geographic authority:

As a veteran-owned business serving food production facilities nationwide for over 40 years, we combine military precision with deep regional understanding of food industry needs.

Our geographic expertise includes:

Project locations demonstrate our reach: From dairy plants in Wisconsin to citrus processors in Florida, from beef facilities in Nebraska to organic produce operations in California, we’ve successfully implemented solutions across diverse environments and requirements, bringing the same commitment to excellence that defines veteran-owned businesses.

Regional considerations we account for:

Build trust through transparency:

Every Custom Conveyor food production system comes with our comprehensive quality guarantee:

Our accountability measures:

Design Documentation

Manufacturing Standards

Installation Verification

Ongoing Support

Credibility-focused close:

When you choose Custom Conveyor, you’re partnering with a veteran-owned company that’s been solving food production challenges since 1984. Our active memberships in IAFP and CEMA ensure we’re always current with food safety standards, while our four decades of hands-on experience means we’ve likely solved challenges similar to yours.

Food safety is non-negotiable – one contamination event can destroy your brand. That’s why leading food processors trust our proven expertise. From preventing cross-contamination to maintaining cold chains, we bring the technical knowledge and practical experience your operation needs.

Connect with our food production experts:

Custom Conveyor – Where four decades of food production expertise meets veteran-owned reliability. Members of the International Association for Food Protection and CEMA. Committed to protecting your products, your consumers, and your brand.

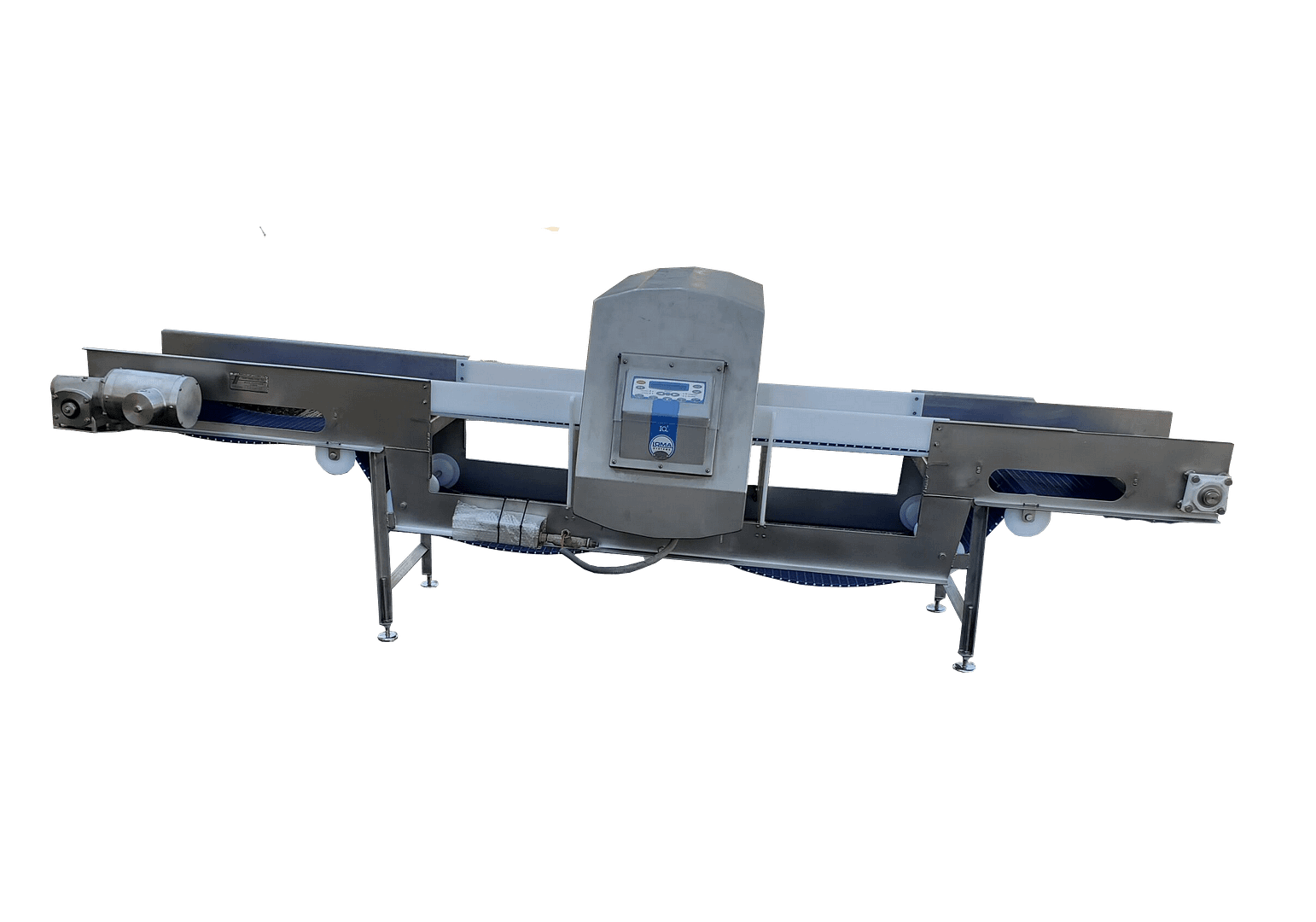

This conveyor was designed to incorporate the customers existing...

If you’d like one of our custom solutions, fill out the form below. A Custom Conveyor Representative will be in touch soon!