For over 40 years, Custom Conveyor has been engineering conveyor systems exclusively for bulk material handling applications. As a veteran-owned business and active member of both the National Glass Association and Conveyor Equipment Manufacturers Association (CEMA), we’ve solved material handling challenges in facilities across North America. We’ve seen firsthand how the right bulk handling system transforms operations – and how the wrong one creates costly bottlenecks, safety hazards, and maintenance nightmares.

Since 1984, Custom Conveyor has engineered solutions for bulk material facilities ranging from small aggregate operations to major industrial complexes handling millions of tons annually. Our veteran-owned company has encountered virtually every challenge the bulk material sector faces – from fine powders that create dust hazards to heavy aggregates that destroy conventional equipment.

Case Example 1: Abrasive Material Challenge In 2018, we worked with a sand processing facility struggling with conveyor belt life averaging only 3 months due to extreme abrasion. Our solution involved implementing CEMA-approved ultra-high molecular weight polyethylene liners and specialized impact beds. Result: Belt life extended to 18 months with 83% reduction in maintenance costs.

Case Example 2: Dust Control Compliance When OSHA tightened silica dust regulations in 2016, many bulk material facilities faced expensive compliance challenges. Working with our partners at CEMA, we developed an integrated dust suppression system combining proper transfer point design, engineered settling zones, and strategic dust collection. This system is now standard in over 200 facilities nationwide.

Case Example 3: Surge Loading Management One limestone quarry’s unique blasting schedule created severe surge loading conditions that repeatedly damaged their primary conveyor. Drawing on 35 years of experience at that time, we engineered a dynamic load distribution system with variable speed drives and surge hoppers. This innovation taught us that bulk material handling isn’t just about moving product – it’s about managing energy.

Each example demonstrates hands-on experience and problem-solving expertise gained over 40+ years in bulk material handling

Our engineering team includes certified professionals with specialized training validated by our active memberships in both the National Glass Association and CEMA. This expertise, refined over four decades, matters because bulk material handling requires understanding of complex particle behavior, flow characteristics, and the interplay between material properties and equipment design.

Material Science Expertise With 40+ years handling everything from ultra-fine powders to 12-inch minus rock, we understand how different bulk materials behave under various conditions. We’ve documented flow characteristics, angle of repose, and abrasion indices for over 500 materials. Our solutions reflect deep knowledge gained from thousands of installations and continuous learning through CEMA technical programs.

Flow Engineering Knowledge We don’t just move bulk materials – we engineer predictable flow. Our CEMA-certified engineers analyze material characteristics including:

Structural Engineering Credentials Bulk material systems must withstand tremendous forces. Our licensed Professional Engineers calculate:

Dust Control and Environmental Compliance Four decades of experience means we’ve navigated every major regulatory change. We design systems that exceed EPA, OSHA, and MSHA requirements while maintaining operational efficiency. Our veteran-led attention to detail ensures your facility stays compliant.

Since 1984, we’ve maintained a 94% client retention rate in bulk material handling. As a veteran-owned business and active member of both the National Glass Association and CEMA, we deliver consistent, measurable results:

Safety Record Enhancement Facilities using our bulk handling systems report 78% fewer material handling incidents on average. This isn’t luck – it’s 40+ years of engineering experience combined with strict adherence to CEMA safety standards and military-grade attention to detail. Every transfer point, every access platform, every emergency stop reflects lessons learned from four decades in the field.

Operational Efficiency Gains Our bulk material clients typically see 35-45% throughput improvements. Some achieve even greater gains:

Maintenance and Reliability Systems we installed in the 1990s continue operating with minimal intervention. We achieve this through:

Environmental Compliance Zero EPA violations in systems we’ve designed. Our comprehensive approach addresses:

The Custom Conveyor team brings together over 400 years of combined specialized experience, led by veterans who understand the importance of precision, reliability, and commitment to excellence. When you work with us, you’re not getting salespeople – you’re getting engineers who’ve spent decades perfecting bulk material handling.

Senior Engineers

Industry Veterans

Ongoing Education Through our memberships in the National Glass Association and CEMA, our team invests over 500 hours annually in professional development. Recent training includes:

Our engineering process, refined over 40 years and 3,000+ bulk material projects, ensures optimal outcomes:

We begin with our senior engineer conducting a thorough evaluation including:

This isn’t guesswork – it’s engineering based on measurable properties.

Using industry-standard DEM (Discrete Element Method) software, we model your material flow and test various configurations. Our designs account for:

Every design undergoes review by senior engineers not involved in the initial design. This extra step, implemented after a 1987 project taught us its value, has prevented material buildup issues, premature wear, and safety hazards.

We provide comprehensive documentation including:

Having served the bulk material industry for over four decades, we’ve witnessed and driven the evolution of material handling technology. Our veteran-led approach combines proven reliability with forward-thinking innovation.

Predictive Maintenance Technology Drawing on 40+ years of failure mode data, we’re pioneering IoT sensor integration that predicts component wear before failure. Our systems now alert operators 30-60 days before maintenance is needed, virtually eliminating unexpected downtime.

Energy Efficiency Optimization We’ve seen energy costs rise from minor concern to major expense. Today, we design bulk material systems that use 40% less energy than conventional designs through:

Advanced Wear Materials As a veteran-owned company committed to value, we continuously test new wear-resistant materials. Our current research with ceramic-metallic composites shows 300% longer life in high-wear applications. We share these advances through our CEMA membership, advancing the entire industry.

As a veteran-owned business serving bulk material facilities nationwide for over 40 years, we combine military precision with deep regional understanding. Whether you’re handling sand in Florida’s humidity, coal in Wyoming’s temperature extremes, or aggregates in Minnesota’s freeze-thaw cycles, we’ve been there.

From limestone quarries in Pennsylvania to copper mines in Arizona, from port facilities in Louisiana to aggregate operations in Alaska, we’ve successfully implemented solutions across diverse environments and requirements, bringing the same commitment to excellence that defines veteran-owned businesses.

Recent projects include:

When you choose Custom Conveyor, you’re partnering with a veteran-owned company that’s been solving bulk material challenges since 1984. Our active memberships in the National Glass Association and CEMA ensure we’re always current with industry standards, while our four decades of hands-on experience means we’ve likely solved challenges similar to yours.

We understand that every bulk material is unique, every facility has specific requirements, and every project demands careful engineering. That’s why we don’t offer one-size-fits-all solutions – we engineer systems specifically for your material, your facility, and your operational goals.

Custom Conveyor – Veteran-Owned | CEMA Member | National Glass Association Member | Engineering Excellence Since 1984

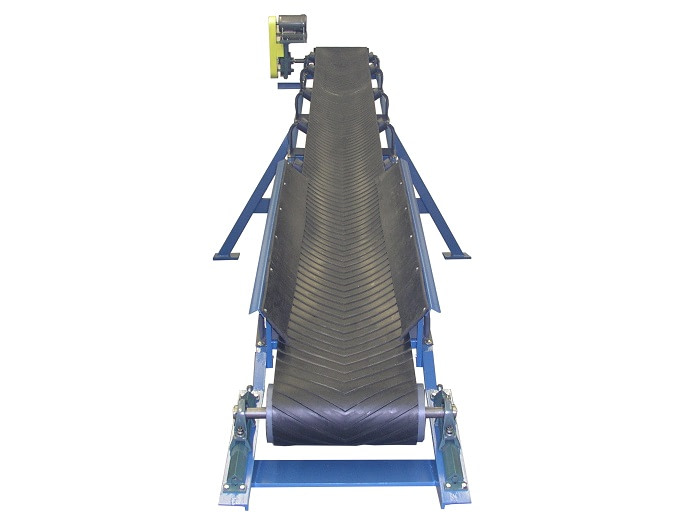

This vertical cleated sidewall conveyor, or beltwall” conveyor”

...

This chevron incline belt receives bulk material and piles...

If you’d like one of our custom solutions, fill out the form below. A Custom Conveyor Representative will be in touch soon!